Part inspection using 3D scanning

02.09.2024

Company Introduction

Benda Tool & Model Works Inc. specializes in the production of precise aluminium and zinc die castings that require machining, surface finishing, and assembly. In addition, the company offers services such as powder coating, electroplating, anodizing, and painting.

Challenge

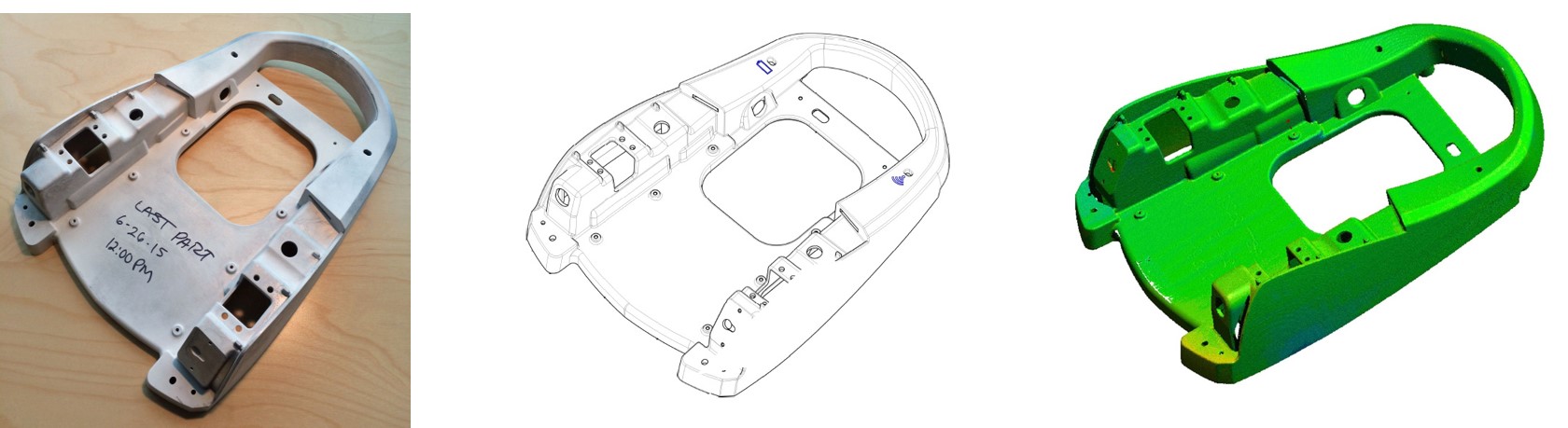

To accelerate the inspection process, Benda Tool & Model Works Inc. started looking for alternatives to traditional measurement using a 3D coordinate measuring machine (CMM). " Our castings tend to be complex in shape, with many curves and contours," explains Gerald Academia, Quality Manager at Benda Tool. " We were looking to get faster feedback and considered adding a scanning head to our CMM, but then decided to look at automated scanners."

Solution

Benda Tool found the optimal solution in the ShapeGrabber scanner. In collaboration with OGP, they selected the ShapeGrabber Ai810 scanner, which is ideal for quickly scanning parts of various sizes and shapes. Today, they use this scanner alongside their CMM for rapid inspection of castings, problem-solving, and providing better feedback to the production department.

Result

"Some of our tool makers don’t perform first article inspections of their moulds, so it’s critical for us to find out if the tool is made properly," says Gerald Academia. "After scanning parts with the ShapeGrabber scanner, we can spot deviations very efficiently and quickly thanks to the colour plots we generate from the 3D scan data. This has shortened our feedback loop with the tool maker because in the past, we might not spot the problem until much later in the production process." In addition to improving product quality and compliance without slowing down production, the new technology has brought other benefits. " Not only are we saving time and effort, we’re improving our interactions with customers because our clients and prospects are always impressed to learn that we’re using advanced inspection technology," adds Academia. " It’s now an important selling point for us in our discussions with customers."