Use of 3D scanner in the production of complex parts

22.05.2024

Introduction

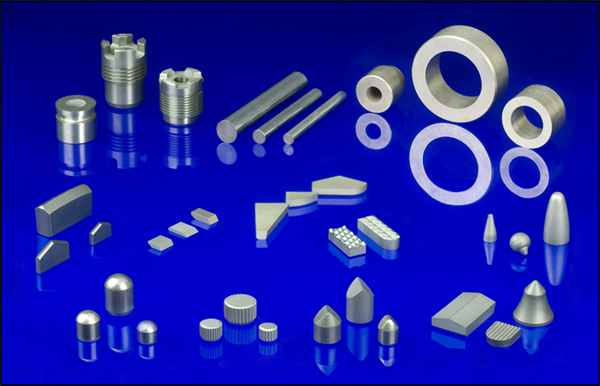

Casmet Supply specializes in the manufacture of complex shaped parts such as drill bits, saw tips, burr blanks and punch dies of various sizes. To ensure the high precision and quality of these parts, the company sought a suitable solution for measuring them. Adam Graham, CEO of Casmet Supply, explains,”We produce a lot of different shapes, such as conical shapes with dome tops or chisel points, that can’t be accurately measured by hand. We also make custom-engineered carbide components that need to be extremely precise.”

Problems when working with carbide

The production of carbide parts is very demanding and places high demands on repeatable measurement. Graham explains, “The carbide itself needs to be mixed with a binder, pressed, sintered and then ground to make these complex shapes," adds Graham. “The pressed shape then shrinks about 20% when it’s put in the sintering furnace, so we need to carefully measure the final product to ensure that it meets the customer’s exact specifications.”

Transition to 3D scanning

Although Casmet Supply had been using standard manual measuring equipment such as calipers for many years, the company was very interested in acquiring its own industrial scanner. "Steve Martin, the owner of the company, is very forward-thinking and supported the idea of trying to incorporate 3D scanners into our production. Steve wanted us to see how a 3D scanner could help our production," explains Graham.

Implementace OGP ShapeGrabberu

Casmet Supply ultimately chose OGP's ShapeGrabber Ai320 to reliably ensure their parts meet the required specifications. This 3D scanner can capture millions of points from even the most complex parts in minutes. These points can then be compared to a 3D model or the correct part.

“The level of automation is excellent,” says Graham. “We check all production parts and now have a digital record for any issues that might arise with customers,” adds Graham. “We can now easily check – and double check – our dies, and perform first article inspection to ensure that everything meets specifications.”

Summary

With OGP's ShapeGrabber Ai320 3D scanner, Casmet Supply has been able to significantly improve the quality control of its products. It enables accurate and fast measurement of complex parts, leading to higher reliability and customer satisfaction. With this step, Casmet Supply has managed to improve its production, but also to strengthen its position in the market as an innovative and technologically advanced company.