Need some advice? Give us a call.

Need some advice? Give us a call.

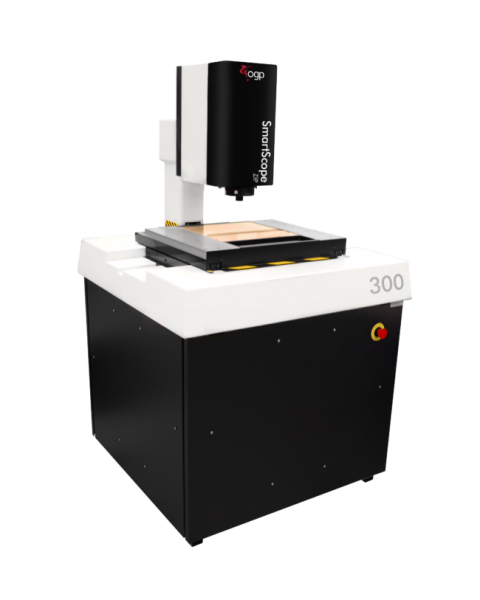

SmartScope® ZIP® systems offer superior optical performance and a range of machine travels to deliver reliable performance. SmartScope ZIP models feature the proven performance of AccuCentric® auto-compensating 7:1 zoom optics. Multiple illumination sources – including monochromatic substage LED profile, white LED TTL surface, SmartRing™ white LED ring light, and optional VuLight™ oblique illuminator – are available to illuminate your toughest measurement challenges.

SmartScope ZIP systems are available in a range of XYZ measurement volumes, from 250 x 150 x 200 mm to 800 x 820 x 300 mm.

ZONE3 metrology software allows for 3D and CAD-based measurement with all sensors.